- Heavy hammer Mobile Crusher 66

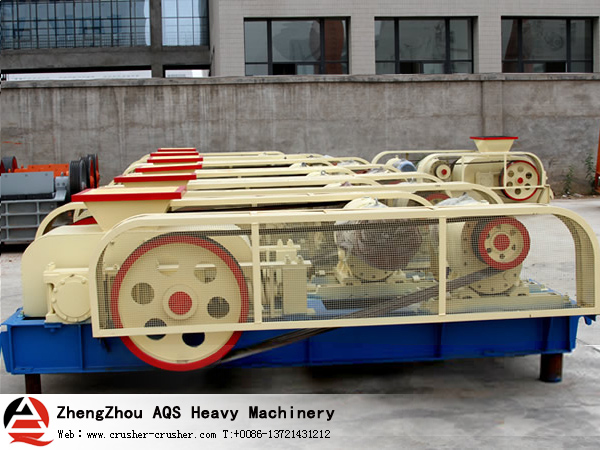

- Roll Crusher 547

- Composite crusher 338

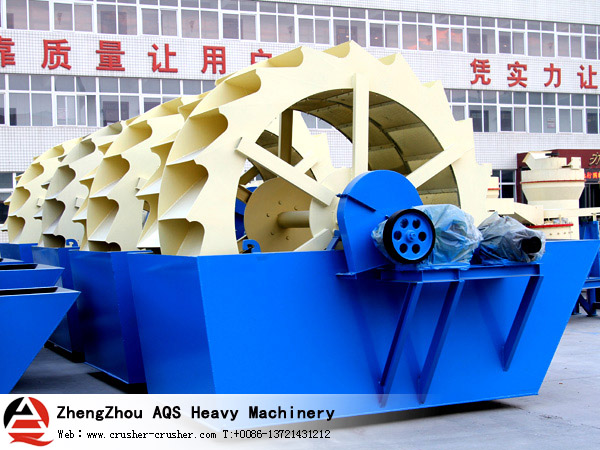

- Wheel Sand Washer 227

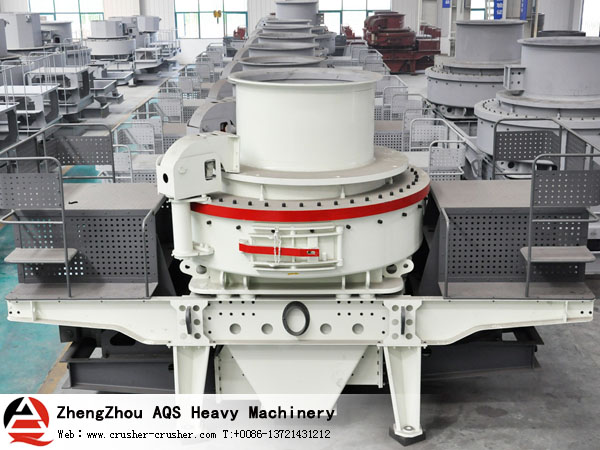

- VSI Sand Maker 209

- Sand recycling machine 126

- Super Ultra-fine Mill 245

- Powder Concentrator 214

- Belt Conveyor 331

- Sand Washer 124

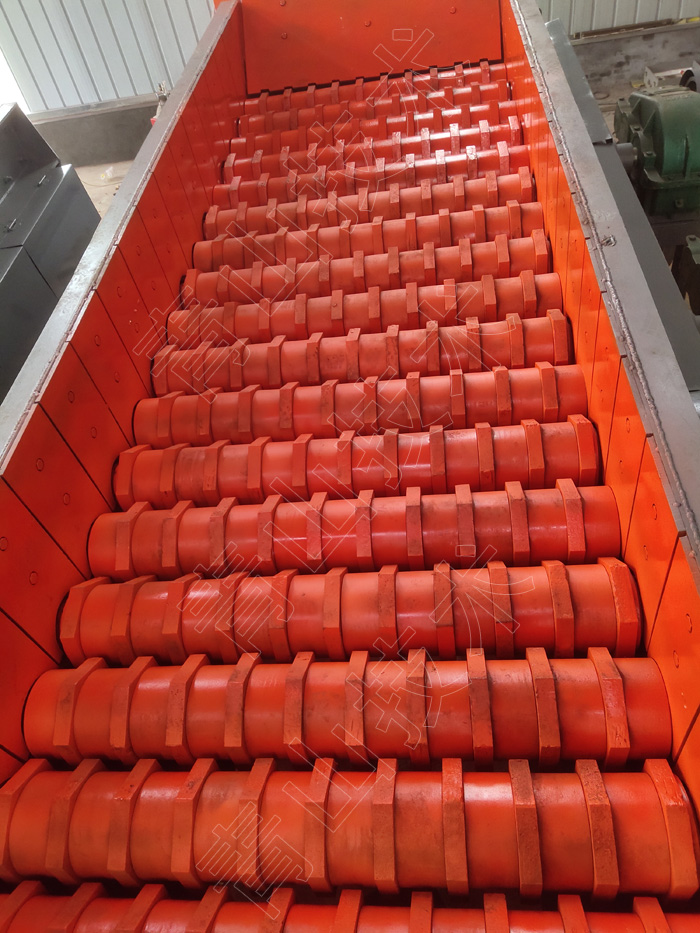

multi-stage linkage roller screen:Mud and Stone Separation Equipment

Multi-stage linkage roller screen (roller screen for short, scientific name equal thickness screen), also known as mud and stone separator, earth rock separator, equal thickness roller screen, butterfly screen, wave roller, etc., is suitable for the separation of mud, sand, ore and other stone materials, all kinds of domestic waste, all kinds of commercial / industrial waste, coal, decoration / construction waste, sticky wet materials, etc. Size, shape classification, so as to reduce the subsequent sorting, crushing equipment load. The wheelbase and disc determine the size of the screening size. The selection size is very wide, and the number of running revolutions can be automatically adjusted according to the material composition and humidity. It not only greatly alleviates the shortage of resources, but also achieves the long-term mechanism of resource recycling.

Working Principle:

The motor drives the wave shaft of the multi-stage device to carry out regular overturning movement. The disc arranged on the roller is used to wave the material forward. The screen surface is composed of a plurality of rotating discs arranged in a straight line. There are equal screen plates arranged on the roller. The roller drives the wheel chain to rotate through the gear. The rotation direction of the roller is consistent with the flow direction of the raw material. There is a gap between the shafts to determine the separation Because the screen shaft is designed according to different running directions, when the material runs in a higher running direction, the speed is faster; when the material runs in a lower running direction, the speed is slower. When the two kinds of materials run at different speeds meet at a certain place on the screen surface, they start to operate axially, so as to improve the screening efficiency. The small particles fall into the bottom of the separator and are sent out by the belt conveyor. It overcomes the screen sticking and blocking problem of various vibrating screens when screening wet materials, and improves the output and reliability of the separation system.

Technical Parameter:

Model | Width (dm) | Length (dm) | Number of axes | Number of motors | Power (kw) | Total Power (kw) | Capacity (t/h) |

AQS-1010 | 10 | 30 | 10 | 2 | 11 | 22 | 112-300 |

AQS-1012 | 10 | 36 | 12 | 2 | 15 | 30 | 135-360 |

AQS-1210 | 12 | 30 | 10 | 2 | 15 | 30 | 135-360 |

AQS-1212 | 1.2 | 36 | 12 | 2 | 15/18.5 | 30/37 | 162-432 |

AQS-1215 | 1.2 | 45 | 15 | 3 | 15 | 45 | 202-540 |

AQS-1515 | 1.5 | 45 | 15 | 3 | 18.5 | 55.5 | 253-675 |

AQS-1518 | 1.5 | 54 | 18 | 3 | 18.5/22 | 55.5/66 | 303-810 |

AQS-1820 | 1.8 | 60 | 20 | 4 | 18.5/22 | 74/88 | 405-1080 |

Delivery real shot: