- Heavy hammer Mobile Crusher 66 Time

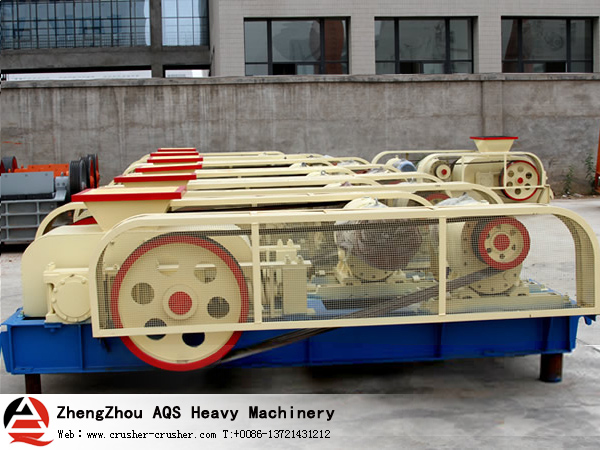

- Roll Crusher 547 Time

- Composite crusher 338 Time

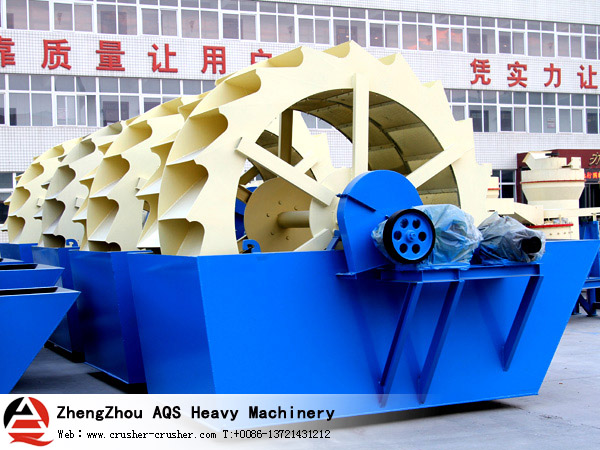

- Wheel Sand Washer 227 Time

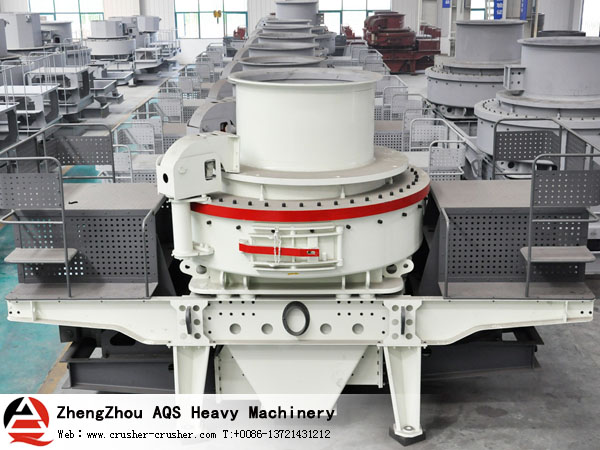

- VSI Sand Maker 209 Time

- Sand recycling machine 126 Time

- Super Ultra-fine Mill 245 Time

- Powder Concentrator 214 Time

- Belt Conveyor 331 Time

- Sand Washer 124 Time

Super Ultra-fine Mill

Introduction

Super Ultrafine Mill adopts the high pressure device, which improves the production capacity and the fineness is adjustable from 80 meshes to 800 meshes. It can process more than 500 materials, such as feldspar, calcite, speckstone, marble, limestone, conductex and pottery clay, etc.

Operation Principle

The operational principle of the mill is same like Raymond roller, but it sets the high pressure spring on the milling equipments, which make the pressure between the roll and the ring increasing 1.2 times. When the roll and the ring wear at certain level, the pressure between the roll and ring can keep constant through adjusting lengthen of the high pressure spring, which ensures the quality stable. At the same time, in order to enlarge the contact area between the roll and the ring at the maximum, the technologies of the spares parts on the milling equipments are improved. This will avoid the phenomenon that the small grits can not be milled by the common mill. Depending on the equation of the gas flow and the result of the stimulation experiment, we changed the geometrical form of the fineness classifier and readjusted the edge dip angle and the relative gap, which makes the super fineness materials being exactly classified.

Technical Parameters

|

Product No.

|

7829

|

8327

|

9531

|

|

|

Roll

|

Quantity

|

3

|

3

|

4

|

|

Diameter (mm)

|

Ф260

|

Ф270

|

Ф310

|

|

|

Height (mm)

|

150

|

140

|

170

|

|

|

Ring

|

Inner Diameter (mm)

|

780

|

830

|

950

|

|

Height (mm)

|

150

|

140

|

170

|

|

|

Feed-in Size (mm)

|

<20

|

<20

|

<20

|

|

|

Finished Products Size (meshes)

|

80-500

|

80-500

|

80-500

|

|

|

capacity(kg/h)

|

280-3000

|

320-3400

|

500-5000

|

|

|

Main Motor Power (kw)

|

18.5

|

18.5

|

37

|

|

|

Fan Motor Power (kw)

|

15

|

18.5

|

30

|

|

|

Classifier Motor Power (kw)

|

4-7.5

|

4-7.5

|

5.5-11

|

|

|

Dimensions(L×W×H)(mm)

|

4500×4200×5100

|

5300×4100×5200

|

7100×5900×7900

|

|

Features

1. Compared with other mills, its capacity increases by 10%-20% under the same power condition, and compression force of rollers to material improve 800-1200kgf under the force of high-pressure spring.

2. Size of final product can be 0.613mm (30mesh) 0.033mm (425mesh). Some can reach the fineness of 0.013mm (1000 mesh).

3. High Pressure Suspension Mill meets the requirement of national dust-dump standard.

4. The separator can be adjusted very easily.

5. The multi-class seals are adopted to keep the grinding equipment tightly closed.