- Heavy hammer Mobile Crusher 66 Time

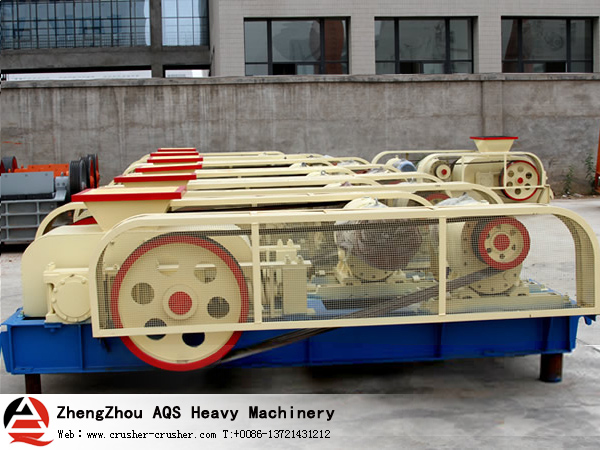

- Roll Crusher 547 Time

- Composite crusher 338 Time

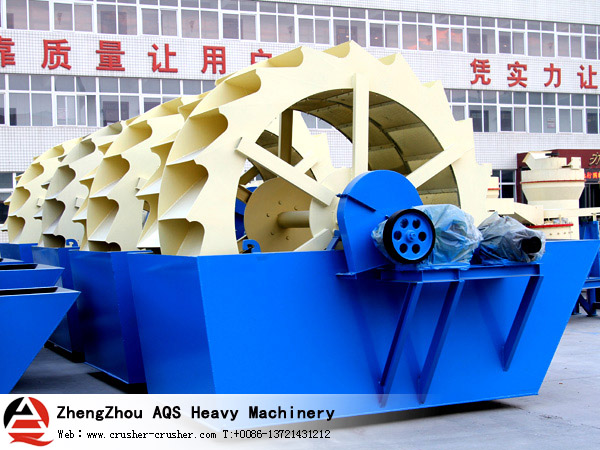

- Wheel Sand Washer 227 Time

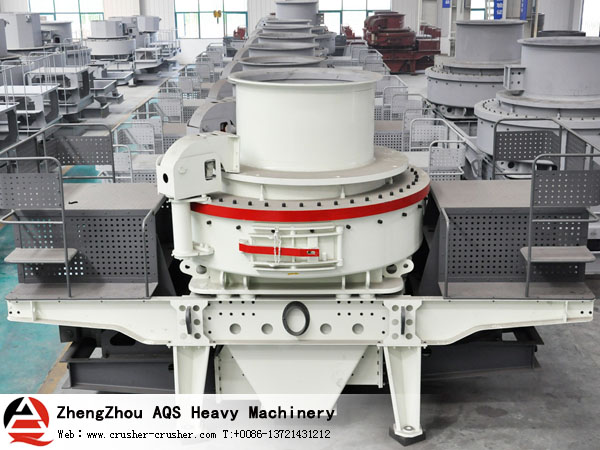

- VSI Sand Maker 209 Time

- Sand recycling machine 126 Time

- Super Ultra-fine Mill 245 Time

- Powder Concentrator 214 Time

- Belt Conveyor 331 Time

- Sand Washer 124 Time

Roll Crusher

The Handling Materials and Application of Roll Crusher:

Mainly used for the crushing of medium or lower-hardness mines and rocks with medium or lower rigidity in mine selection, chemicals, cement and building materials industrial production.

Technical Parameter:

Model | 2PG0425 | 2PG0640 | 2PG0740 | 2PG0850 | 2PG1060 | 2PG1260 | 2PG1560 |

Roller diameter(mm) | Ф400 | Ф610 | Ф700 | Ф800 | Ф1000 | Ф1200 | Ф1500 |

Roller width(mm) | 250 | 400 | 400 | 500 | 600 | 600 | 600 |

Input Size(mm) | ≤25 | ≤25 | ≤25 | ≤25 | ≤30 | ≤30 | ≤30 |

Discharging Gate(mm) | 2-8 | 2-8 | 2-8 | 2-8 | 2-10 | 2-10 | 2-10 |

Processing capacity(t/h) | 5-10 | 10-20 | 15-30 | 20-40 | 30-50 | 40-70 | 60-110 |

Power Models | Y132M-6 | Y180L-6 | Y200L-4 | Y225M-4 | Y250M-4 | Y315M-6 | Y315L-6 |

Motor power(kw) | 5.5×2 | 15×2 | 30×2 | 45×2 | 55×2 | 75×2 | 110×2 |

Total weight(t) | 2.2 | 5.9 | 9.8 | 13.5 | 17.2 | 28.5 | 39.3 |

The Interior Structure of Roll Crusher:

The main composing parts of the wheel gear driving device include the fixed roller, movable roller, driving shaft, machine frame, underbed, cover piece and long gear cover.

The Working Process of Roll Crusher:

The double roll crusher is driven by the belt conveyor of the electric motor, and through a pair of middle reduction gear rolls, the fixed roll will rotate; and relying on a pair of long gears on the other side of the fixed roll, the movable roll is driven to move, and the two rolls will move in a relative motion in order to squeeze the materials.

Product features:

1. Fote double roll crusher and teeth roll crusher are mainly composed of roller bearing, roller support bearing, compacting and adjusting device, driving unit and other components.

2. Adjustment of discharging granularity: there is a wedge or shim adjusting device between two rollers, when the adjusting bolt pulls the wedge up, the wedge rolls the moving roller away, that is, the gap between two rollers will get bigger and the feed size gets bigger; when the wedge is down, the gap between the two rollers will get small under the impact of pressure spring, the feeding size of roller crusher gets small.

3. The drive mechanism of Fote roll crusher or roller crusher consists of two electric motors, which rotates according to comparative direction by means of chains or V-belt transmission onto the grooved wheel dragging rollers. When crushing he materials, materials from the inlet through the roller, will be crushed through rolling and the crushed materials will be discharged from the under frame.

4. For safety, the chain or belt of the driving part of teeth roll crusher and double roll crusher will be installed safety shields according to actual conditions. We should pay special attention to the following matters in the work of roll crusher. We should strength the work of iron ore removing. The non-crushing (drill bit) can damage the roll crusher or roller crusher once they have felt into the rollers, thus resulting in stopping accidents. So, we should install iron removal device before the using of crushers.