- Heavy hammer Mobile Crusher 66 Time

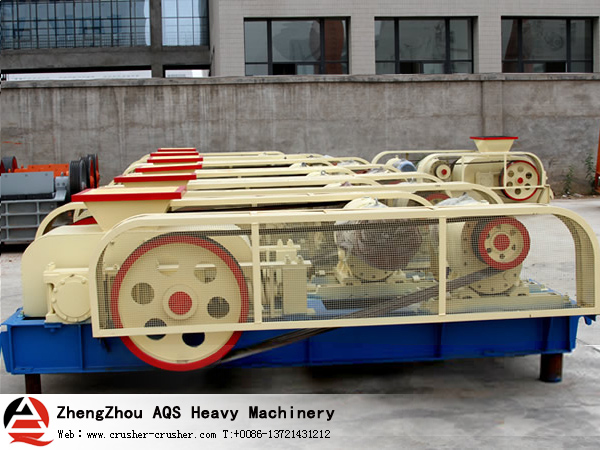

- Roll Crusher 547 Time

- Composite crusher 338 Time

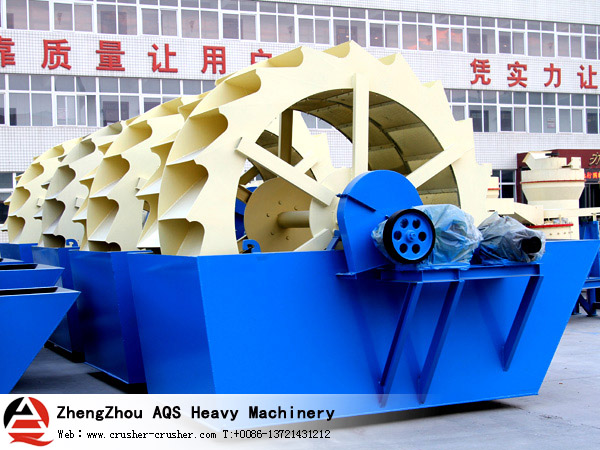

- Wheel Sand Washer 227 Time

- VSI Sand Maker 209 Time

- Sand recycling machine 126 Time

- Super Ultra-fine Mill 245 Time

- Powder Concentrator 214 Time

- Belt Conveyor 331 Time

- Sand Washer 124 Time

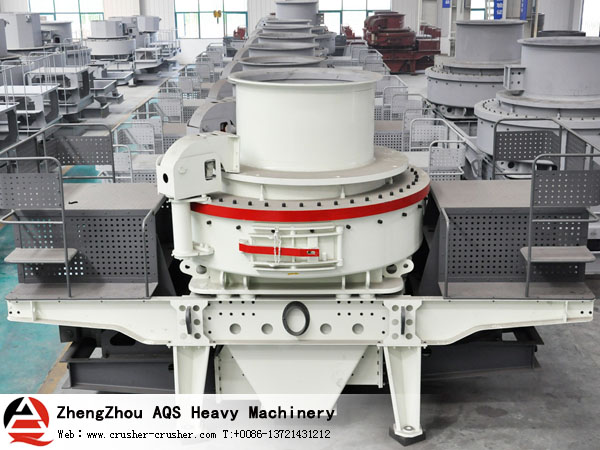

VSI Sand Maker

VSI Sand Maker is suitable for crushing and shaping soft or middle-hard or extremely hard materials, widely applied to pebble, rocks (limestone, granite, basalt, dolerite, andesite), iron ore tailings, artificial sand making of stone chips. Water conservancy and hydropower of engineering field, high-grade highways, expressway and railway, passenger railway, bridge, airport pavement, municipal engineering, sand manufacturing and aggregated rock shaping.

VSI Impact Sand maker is called as VSI Sand Maker for short, also called as The Third Generation Sand Maker or New-type Sand Maker. SANME introduced German technology, developed and manufactured this international level high performance new-type sand making equipment; it places an irreplaceable role in fine crushing.

Working principle of VSI Sand Maker:

The materials fall into impeller with high-speed rotation vertically. On the force of high-speed centrifugal, the materials strike to the other part of material in a high speed. After mutual impacting, the materials will strike and rub between the impeller and the casing and then be discharged straight from the lower portion to form a closed multiple cycles. Final product is controlled by screening equipment to meet the requirement.

Technical Data of VSI Sand Maker

Model | Max Feed Size(mm) | Rotor Speed(r/min) | Capacity(t/h) | Motor Power(kw) | Weight(kg) |

VSI-3000 | 45(70) | 1700-2000 | 30-60 | 75-90 | ≤5310 |

VSI-4000 | 55(70) | 1400-1620 | 50-90 | 110-150 | ≤7840 |

VSI-5000 | 65(80) | 1330-1530 | 80-150 | 180-264 | ≤11200 |

VSI-6000 | 70(100) | 1200-1400 | 120-250 | 264-320 | ≤14590 |

VSI-7000 | 70(100) | 1000-1200 | 180-350 | 320-400 | ≤16580 |

VSI-8000 | 80(150) | 1000-1100 | 250-380 | 400-440 | ≤23450 |

VSI-9000 | 80(150) | 1000-1100 | 380-600 | 440-630 | ≤23980 |

Application Range of VSI Sand Maker

1、Pebble

The main chemical component of pebble is silicon dioxide, followed by little iron oxide, manganese, copper, aluminum, magnesium, etc and compound.

2、Basalt

The main component of basalt is composed of basic feldspar and pyroxene, followed by olivine, hornblende and black mica, etc, with dead color, being black generally.

3、Limestone

The main component of limestone is CaCO3 which can be used as construction materials; it is also the important raw materials for many industries.

4、Weathered Stone

The weathered stone is also called as moiré stone, aggregated by kinds of broken stones, alternated with different color, mainly composed of carboniferous rocks.

Features and technology advantages:

1.Simple and reasonable structure, low cost

2.High crushing ratio, energy saving

3.Fine crush and grind

4.Moisture content of raw material up to about 8%

5.Suitable for crushing hard material

6.Excellent shape of final product

7.Small abrasion, easy maintenance

8.Noise when working is below 75dB

Technological process for artificial sand making production line

1、The aggregate with size of 0-40mm pass through suspended-type vibrating feeder, than being transported to VSI sand maker by the rubble conveyor for crushing, the crushed materials will be transported to a two-deck vibrating screen for screening;

2、The materials with size being smaller than 3mm will enter powder separator which will process the materials with size of 0-0.075mm, 0.075-3mm and 3-5mm respectively, then composing to be finished material pile;

3、The materials with size being larger than 5mm will be returned to the sand maker for re-crushing, forming a closed cycle. According output requirements, part of the materials with the size between 3-5mm can be the finished products, and part can be returned to the sand maker for re-crushing;

4、Impulse pocket-type dust remover can be configured according to environmental-protection requirements.