- Heavy hammer Mobile Crusher 66 Time

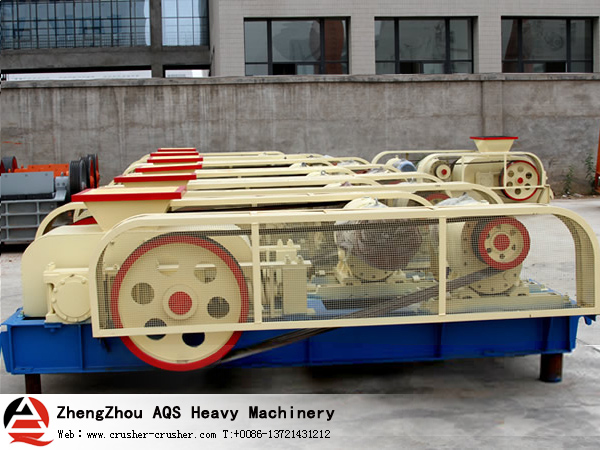

- Roll Crusher 547 Time

- Composite crusher 338 Time

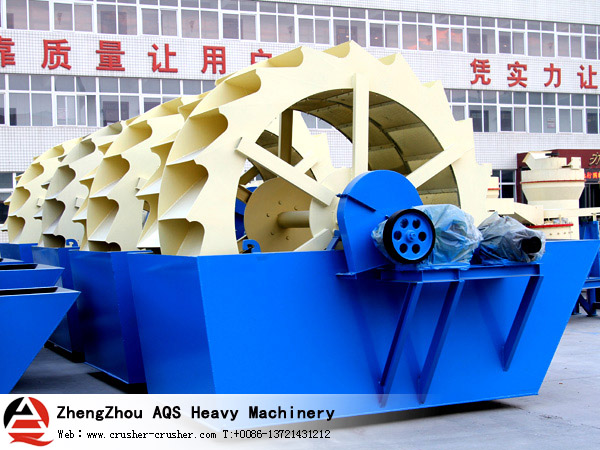

- Wheel Sand Washer 227 Time

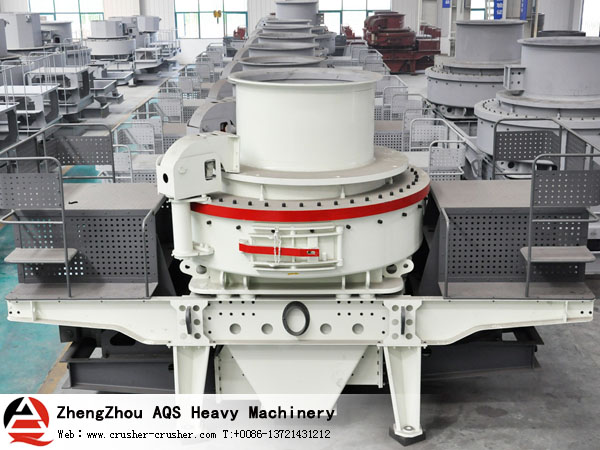

- VSI Sand Maker 209 Time

- Sand recycling machine 126 Time

- Super Ultra-fine Mill 245 Time

- Powder Concentrator 214 Time

- Belt Conveyor 331 Time

- Sand Washer 124 Time

Raymond Mill

Introduction

Raymond mill is used for grinding the barite, limestone, kaolin, cement, slag, etc, below scale 9.3 of Mohs hardness and 280-odd sorts of non-inflammable and nonexclusive stuff in the trades of mining, metallurgical industrial, chemical engineering and building material for high fine powder generation and processing. The product size is adjustable in the range of 80-325 (600 the largest) meshes. It is possible to produce 30-80 mesh coarse powder through special device in the machine.

Operation Principle

Firstly, raw material is crushed by jaw crusher to the size required, and then the crushed materials are elevated into a hopper from which the material is transported through the electro-magnetic vibrating feeder evenly and continuously into the grinding chamber for powder-processing. The rollers oscillate outward to press the ring because of the centrifugal force and the shovel scoops up the materials, send to the middle between ring and roller to accomplish the grind. After this, the ground stuff is carried by the air from the blower into the separator for screening. The fine powers are blow into the cyclone collector and are poured out through the output-powder valve as the final products and the rough stuff after the screening will be recycled back into the grinding chamber for regrinding. The airflow system is closely sealed up and circulated under condition of negative and positive pressure.

Technical Parameter

Model Data | 3R1410 | 3R2115 | 3R2615 | 3R2714 | 4R2714 |

Max.Feeding Size (mm) | 5-8 | 15 | 20 | 20 | 15-25 |

Fineness Of Product (mm) | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 |

Capacity/Shift(t/8h) (Range Diff Materials) | 1-10 | 1-18 | 2-25 | 2-28 | 3-30 |

Speed (r/m) | 280 | 180 | 170 | 170 | 170 |

Inner ring Diameter (mm) | Φ405 | Φ640 | Φ780 | Φ830 | Φ830 |

Roller Diameter (mm) | Φ140 | Φ210 | Φ260 | Φ270 | Φ270 |

Height (mm) | 100 | 150 | 150 | 140 | 140 |

Main Motor Power (kw) | Y160M-6-7.5 | Y200L-8-15 | Y225S-8-18.5 | Y255M-8-18.5 | Y225M-8-22 |

Fan Motor Model (kw) | Y132S-4-5.5 | Y132M-4-11 | Y180M-4-15 | Y180M-4-18.5 | Y180M-4-18.5 |

Classifier Motor(kw) | Y90L-6-2.2 | Y112M-6-2.2 | Y112M-6-2.2 | Y112M-6-2.2 | Y112M-6-2.2 |

Dimensions (mm) | 3340×2161×3246 | 4500×2800×5000 | 5970×4000×5000 | 5970×4000×5000 | 5970×4000×5000 |

Weight (kg) | 2500 | 3100 | 3800 | 3850 | 3900 |

Model Data | 3R3016 | 4R3016 | 4R3216 | 5R4119 | 6R4525 |

Max.Feeding Size (mm) | 15-25 | 15-25 | 25 | 30 | 30 |

Fineness Of Product (mm) | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 |

Capacity/Shift(t/8h) (Range Diff Materials) | 3-34 | 3-36 | 3-38 | 6-76 | 10-120 |

Speed (r/m) | 178 | 178 | 130 | 105 | 82 |

Inner ring Diameter (mm) | Φ910 | Φ910 | Φ970 | Φ1280 | Φ1770 |

Roller Diameter (mm) | Φ300 | Φ300 | Φ320 | Φ410 | Φ450 |

Height (mm) | 160 | 160 | 160 | 190 | 250 |

Main Motor Power (kw) | Y225M-8-30 | Y225M-8-30 | Y225S-4-37 | Y280S-4-75 | Y315M-4-132 |

Fan Motor Model (kw) | Y180L-4-22 | Y180L-4-22 | Y220M-4-30 | Y25M-4-55 | Y315M-4-132 |

Classifier Motor(kw) | Y132S-6-3 | Y132S-6-3 | YC1200-4A-5.5 | YC1200-4B-7.5 | Y160M-4-11 |

Dimensions (mm) | 7500×4500×6200 | 7500×4500×6200 | 9900×5800×8500 | 7850×8000×9700 | 8850×10500×1100 |

Weight (kg) | 7000 | 7500 | 14000 | 257000 | 470000 |

Features

1.Fine powder produced

2.High efficiency

3.Wide adjustable product size,80-425 meshes

4.Low noise, little pollution