- Heavy hammer Mobile Crusher 66 Time

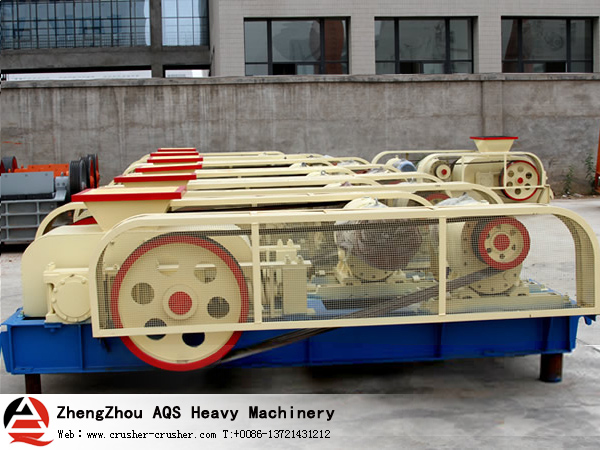

- Roll Crusher 547 Time

- Composite crusher 338 Time

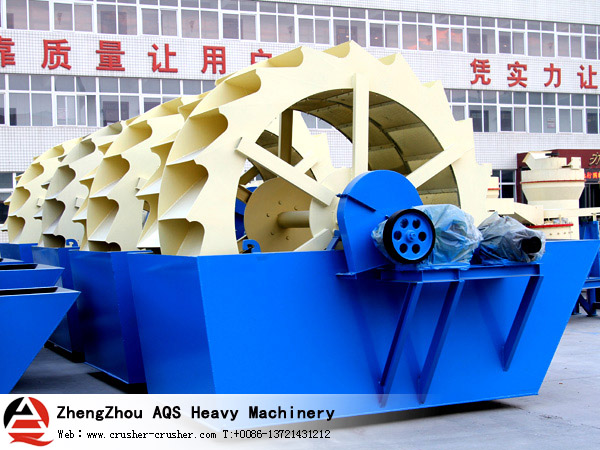

- Wheel Sand Washer 227 Time

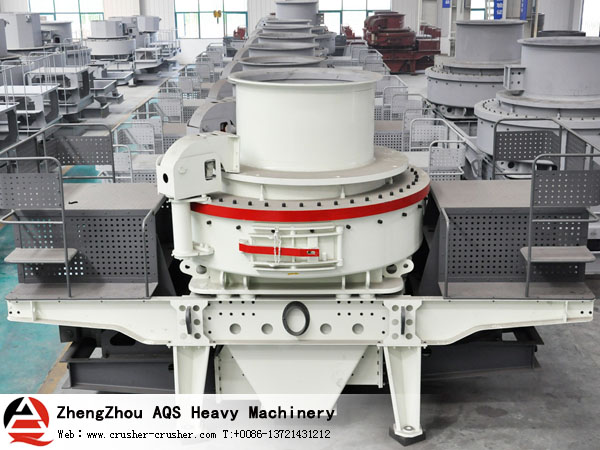

- VSI Sand Maker 209 Time

- Sand recycling machine 126 Time

- Super Ultra-fine Mill 245 Time

- Powder Concentrator 214 Time

- Belt Conveyor 331 Time

- Sand Washer 124 Time

circular vibrating screen

YK series circular vibrating screen system to introduce German technology to produce efficient vibrating screen, adjustable amplitude, long material screening line, multi-layer screening, clear all specifications screening, screening efficiency. Suitable quarry screening aggregate, coal preparation, mineral processing, building materials, electricity and chemical industries are also available for product grading.

Circular vibrating screen works:

Motor through V-belt exciter eccentric block to produce the high-speed rotation. Operation of the eccentric block to produce great centrifugal force to stimulate sieve box to produce a certain amplitude circular motion, sieve material in the the tilt screen surface by the impulse to pass by the screen box and generate continuous movement of throwing materials with the screen surface meet manipulation smaller than the sieve particles through sieve, in order to achieve the classification.

Circular vibrating screen composition:

Circular vibrating sieve machine is mainly composed of screen box, screen mesh, vibrator, damping spring device, chassis. Cylinder eccentric shaft vibration exciter and partial block help to adjust the amplitude of the vibrator is mounted on the side panel of the screen box is rotated by the motor through the V-belt to produce centrifugal force, forcing the vibration of screen box. The side panel of the screen machine made made of high quality steel, side panels and beams, shaker base is made of high strength bolts or ring groove rivet connection. The vibrator mounted on the side plate of the sieve box, is rotated by a motor via a coupling, a centrifugal inertial force, forcing the sieve vibration.

Circular vibrating screen structural features:

1,Using block eccentric as excitation force, strong exciting force;

2 sieve beams and screen box with high strength bolts links, no welding;

3,Sieve machine of simple structure, convenient maintenance;

4,Tire couplings, flexible connection, smooth operation;

5,Screening efficiency, large capacity, long life.

Circular vibrating screen use and maintenance:

Vibrating screen should start in the screen surface materials, try to avoid strip boot the screen machine running smooth before I can give material. Downtime should stop feeding, to be surface materials exclude and then stop. The course of their work should always observe the screen machine operation, such as the movement is not normal or abnormal sound down to check and find out the reasons and troubleshooting.

YK circular vibrating screen Technical Data:

| Model | Screen Deck | Installation Slope | Deck Size (㎡) | Vibration Frequency (r/min) | Double Amplitude (mm) | Capacity(t/h) | Motor Power(Kw) | Overall Dimensions (L×W×H) (mm) | Weight (Kg) |

| YK1235 | 1 | 15 | 4.2 | 970 | 6-8 | 35-180 | 5.5 | 3729x2443x1547 | 1845 |

| 2YK1235 | 2 | 15 | 4.2 | 970 | 6-8 | 40-150 | 5.5 | 3924x2433x2349 | 2982 |

| 3YK1235 | 3 | 15 | 4.2 | 970 | 6-8 | 25-270 | 7.5 | 3924x2527x2713 | 3922 |

| 4YK1235 | 4 | 15 | 4.2 | 970 | 6-8 | 25-270 | 11 | 3924x2688x3126 | 4821 |

| YK1545 | 1 | 17.5 | 6.75 | 970 | 6-8 | 63-315 | 11 | 4913x2943x2164 | 3362 |

| 2YK1545 | 2 | 17.5 | 6.75 | 970 | 6-8 | 200-300 | 15 | 5163x3090x3156 | 5113 |

| 3YK1545 | 3 | 17.5 | 6.75 | 970 | 6-8 | 35-378 | 15 | 5163x3040x3513 | 6251 |

| 4YK1545 | 4 | 17.5 | 6.75 | 970 | 6-8 | 200-300 | 18.5 | 5163x3155x3804 | 7519 |

| YK1548 | 1 | 17.5 | 7.2 | 970 | 6-8 | 63-315 | 11 | 5199x2943x2171 | 3418 |

| 2YK1548 | 2 | 17.5 | 7.2 | 970 | 6-8 | 200-300 | 15 | 5449x3090x3201 | 5266 |

| 3YK1548 | 3 | 17.5 | 7.2 | 970 | 6-8 | 35-378 | 15 | 5449x3090x3558 | 6453 |

| 4YK1548 | 4 | 17.5 | 7.2 | 970 | 6-8 | 47-275 | 18.5 | 5449x3155x3909 | 7845 |

| YK1860 | 1 | 20 | 10.8 | 970 | 6-8 | 52-567 | 15 | 6302×3390×2992 | 4572 |

| 2YK1860 | 2 | 20 | 10.8 | 970 | 6-8 | 200-300 | 18.5 | 6020×3455×3756 | 5808 |

| 3YK1860 | 3 | 20 | 10.8 | 970 | 6-8 | 52-567 | 18.5 | 6020×3455×4180 | 7349 |

| 4YK1860 | 4 | 20 | 10.8 | 970 | 6-8 | 52-567 | 22 | 6183x3545x4521 | 8809 |

| YK2160 | 1 | 20 | 12.6 | 970 | 6-8 | 200-300 | 18.5 | 6302×3755×2992 | 4940 |

| 2YK2160 | 2 | 20 | 12.6 | 970 | 6-8 | 66-720 | 22 | 6184x3755x3814 | 6438 |

| 3YK2160 | 3 | 20 | 12.6 | 970 | 6-8 | 66-720 | 30 | 6184x3915x4239 | 8665 |

| 4YK2160 | 4 | 20 | 12.6 | 970 | 6-8 | 66-720 | 30 | 6176x3915x4521 | 9933 |

| YK2460 | 1 | 20 | 14.4 | 970 | 6-8 | 200-300 | 18.5 | 6302×4105×2992 | 5496 |

| 2YK2460 | 2 | 20 | 14.4 | 970 | 6-8 | 79-864 | 30 | 6184x4265x4032 | 8090 |

| 3YK2460 | 3 | 20 | 14.4 | 840 | 7-9 | 79-864 | 30 | 6184x4284x4510 | 11255 |

| 4YK2460 | 4 | 20 | 14.4 | 840 | 6-8 | 79-864 | 30 | 6181x4284x4787 | 13400 |

| YK2475 | 1 | 20 | 18 | 840 | 6-8 | 200-300 | 20 | 7664x4115x3522 | 7004 |

| 2YK2475 | 2 | 20 | 18 | 840 | 6-8 | 79-864 | 30 | 7875x4249x4667 | 10685 |

| 3YK2475 | 3 | 20 | 18 | 840 | 6-8 | 99-1080 | 37 | 7875x4263x5126 | 12727 |

| 4YK2475 | 4 | 20 | 18 | 840 | 6-8 | 99-1080 | 45 | 7781x4294x5388 | 15822 |

| YK3060 | 1 | 20 | 18 | 840 | 6-8 | 99-1080 | 30 | 6312x4845x3029 | 9063 |

| 2YK3060 | 2 | 20 | 18 | 840 | 6-8 | 99-1080 | 37 | 6369x4831x4263 | 12617 |

| 3YK3060 | 3 | 20 | 18 | 840 | 6-8 | 99-1080 | 45 | 6369x4902x4738 | 15644 |

| 4YKD3060 | 4 | 20 | 18 | 840 | 6-8 | 80-860 | 2x30 | 6316x5066x5264 | 22189 |

| YK3075 | 1 | 20 | 22.5 | 840 | 6-8 | 66-720 | 37 | 7627x4823x3494 | 10871 |

| 2YK3075 | 2 | 20 | 22.5 | 840 | 6-8 | 99-1080 | 45 | 7872x4909x4817 | 17263 |

| 2YKD3075 | 2 | 20 | 22.5 | 840 | 6-8 | 80-860 | 2x30 | 7814x5072x4854 | 20194 |

| 3YK3075 | 3 | 20 | 22.5 | 840 | 6-8 | 99-1080 | 55 | 7877x4912x5287 | 18713 |

| 3YKD3075 | 3 | 20 | 22.5 | 840 | 6-8 | 100-1080 | 2x30 | 7819x5072x5293 | 21717 |

Note:The processing capacity listed in the table is based on dry classification of limestone,which bulk density is 1.6t/m³.The listed capacity is only for reference.The actual data need to be fixed by tech department according to worksite situation.