- Heavy hammer Mobile Crusher 66

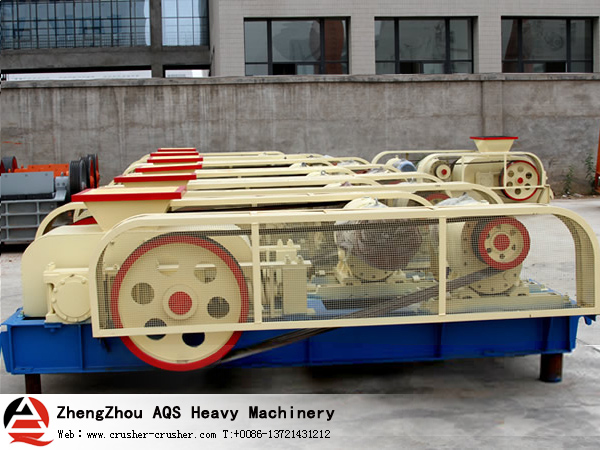

- Roll Crusher 547

- Composite crusher 338

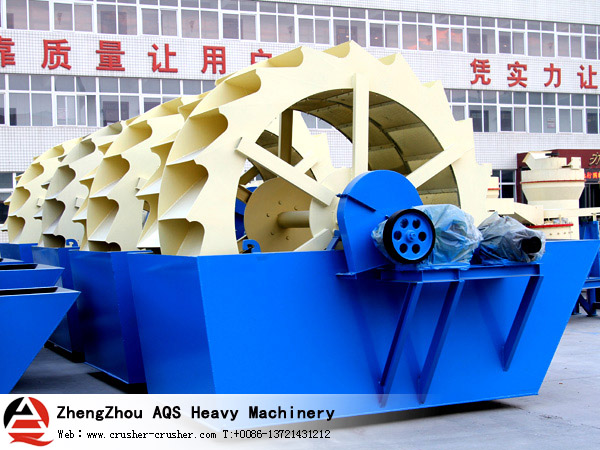

- Wheel Sand Washer 227

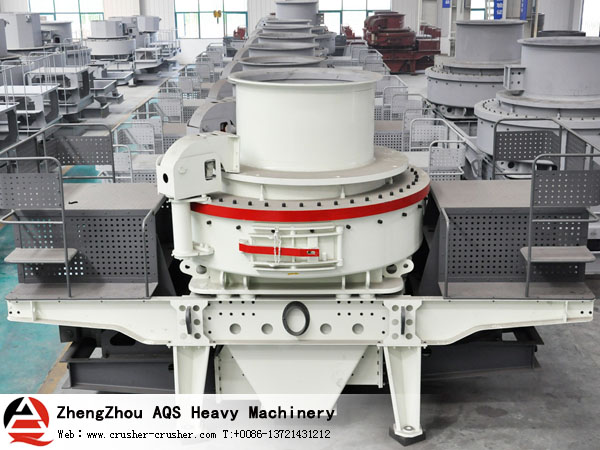

- VSI Sand Maker 209

- Sand recycling machine 126

- Super Ultra-fine Mill 245

- Powder Concentrator 214

- Belt Conveyor 331

- Sand Washer 124

Impact High-efficient Sand Maker most efficient

With the digestion and absorption of the advanced technology and connecting the working conditions of the ralated industries, the Reaction High efficiency Sand Maker is newly researched and high efficient sand maker. It is widely used in fine crushing of many minerals, such as granite, basalt, limestone, cobble, cement clinker, quartzite, iron ore and bauxite etc. And it also can produce the superior aggregate materials for the using areas of high-level road, railway, hydroelectricity, airport, cement, resistance materials and metallurgy, etc.

Operation Principle

This is kind of continuous operation equipment. When operating, the rotor is running at a high speed by the drive of motor, and materials enter into the 1st cavity to be crushed, and then get into the 2nd fineness cavity to be broken, finally being discharged from the discharging opening.

Technical Parameters

Model | Feed Opening Size(mm) | Max Feed Size(mm) | Discharging Size (mm) | Range Of Discharging Opening Gap(mm) | capacity(t/h) | Power (Kw) | ||

Cement Clinker | Limestone | Glass Sand | ||||||

800×400 | 400×230 | 120 | ≤5 | 5-20 | 20-30 | 30-45 | 35-45 | 22-37 |

800×600 | 600×230 | 180 | ≤5 | 5-20 | 35-40 | 40-55 | 45-55 | 37-45 |

800×800 | 800×230 | 180 | ≤5 | 5-20 | 35-45 | 60-65 | 55-65 | 45-55 |

1010×1010 | 1000×330 | 180 | ≤5 | 5-20 | 45-55 | 60-75 | 65-75 | 55-75 |

1200×1000 | 1200×330 | 180 | ≤5 | 5-20 | 80-110 | 80-100 | 80-100 | 90-110 |

1200×1200 | 1200×420 | 180 | ≤5 | 5-20 | 100-110 | 90-100 | 90-120 | 110-132 |

1400×1400 | 1400×420 | 190 | ≤5 | 5-20 | 100-150 | 100-150 | 120-150 | 160 |

1600×1600 | 1600×520 | 190 | ≤5 | 5-20 | 170-210 | 190-250 | 190-250 | 250 |

1800×1800 | 1800×520 | 190 | ≤5 | 5-20 | 250-270 | 280-310 | 280-310 | 315 |

Features

1.Small and equal feeding out size

2.High production capacity

3.Long service life ,low supporting power

4.Changing the three grades crushing to two grades crushing

5. Simple structure, easy maintenance and stable operation