- Heavy hammer Mobile Crusher 66

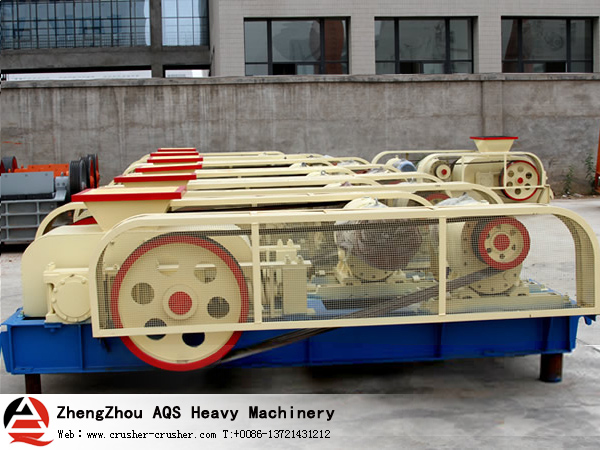

- Roll Crusher 547

- Composite crusher 338

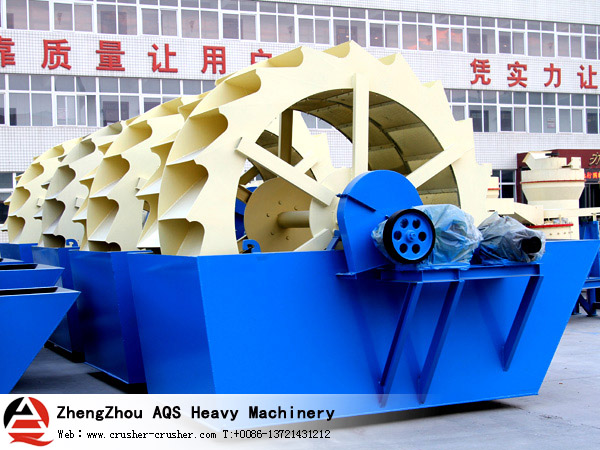

- Wheel Sand Washer 227

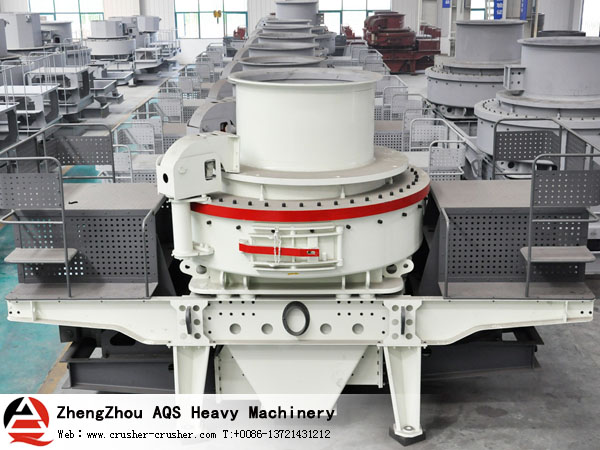

- VSI Sand Maker 209

- Sand recycling machine 126

- Super Ultra-fine Mill 245

- Powder Concentrator 214

- Belt Conveyor 331

- Sand Washer 124

Jaw Crusher‘s common malfunction and its remedy

Jaw Crusher common symptom1:a suddenly stop of the host (commonly known as: boring car).

Reasons:1)the block of discharge port lead the sealing; 2)the loose of rotation of the belt driving sheave rotating make the belt slip; 3)eccentric shaft bush sleeve is loose, causing the rack bearing no gaps in both sides, so that the eccentric shaft stuck, unable to turn; 4)workplace voltage is too low, which causes the host encounter aniseed,and the inability broken; 5) bearing damage.

Remedy:1)removing obstruction of the discharge opening to ensure the smooth flow of materials; 2)tighten or replace belt; 3)to re-install or replace the bush sleeve; 4)align the workplace voltage to conform to the requirements of the host operating voltage; 5)replacement bearing.

Symptom 2:the host sheave and moving jaw functioning normally, but broken cease work.

Reasons:1)tension spring break; 2)rod fracture; 3)off or broken of the bracket

Remedy:1)replace tension spring; 2)replace the rod; 3)to re-install or replace the bracket

Symptom 3:stunned Crusher spring break.

Reason: emphasis on small Jaw Crusher discharge opening with the spring tention.

Remedy: Replace the spring.

Symptom 4:flying sheave shaft swing.

Reasons:1) flying sheave shaft hole slot, flat key or shaft wear and loose in coordinating; 2)stone rolling into the inside of the wheel result in cracking of the flying sheave wheel shell; 3)casting defects; 4)flying sheave expansion sleeve looses.

Remedy:1)flat key wear, replace the flat key, or replace the eccentric shaft or fly wheel slot; 2)by doing flying tank round shield and replace the eccentric shaft or fly wheel slot; 3)replace the eccentric shaft or tank round. 4)Re-tight set up sleeve

Symptom 5:there is beating and crash sound in the process of moving or fixing the jaw plate .

Reasons:1)fastening bolts of jaw Crusher’s jaw plate loose or falling; 2)jaw Crusher’s discharge opening is too small lead the bottom two jaw plates hit each other.

Remedy:1)fixed or installed for tight bolts; 2)align the nesting population to ensure that the correct gap between two jaw plate.